Mp Filtri Spa components are essential for maintaining clean and efficient hydraulic systems, crucial for various industrial applications. Whether you’re dealing with construction equipment, agricultural machinery, or industrial processes, understanding the importance of MP Filtri spa products can significantly impact your operations. This guide delves into the world of MP Filtri spa, exploring their benefits, applications, and how they contribute to maximizing the lifespan of your hydraulic systems.

The Importance of MP Filtri Spa in Hydraulic Systems

Hydraulic systems are the powerhouse behind many industrial operations. Their efficiency and reliability directly impact productivity and downtime. Contaminants like dust, metal shavings, and water can wreak havoc on these systems, leading to costly repairs and decreased performance. MP Filtri spa filtration products play a vital role in safeguarding your hydraulic systems by removing these harmful particles, ensuring smooth operation and extended equipment life. Choosing the right MP Filtri spa component is essential for optimizing performance and protecting your investment.

Proper filtration prevents premature wear and tear of critical components like pumps, valves, and actuators. By removing contaminants, MP Filtri spa filters maintain the integrity of the hydraulic fluid, minimizing friction and maximizing efficiency. This translates to reduced maintenance costs, improved productivity, and a longer lifespan for your valuable equipment.

Exploring the Range of MP Filtri Spa Products

MP Filtri spa offers a comprehensive range of filtration solutions catering to diverse industrial needs. From return line filters to pressure filters and off-line filtration systems, their product portfolio covers a wide spectrum of applications. Understanding the specific requirements of your hydraulic system is crucial for selecting the appropriate MP Filtri spa product.

Their product line includes:

- Return Line Filters: Designed to remove contaminants from the hydraulic fluid returning to the reservoir, protecting the pump and other sensitive components.

- Pressure Filters: Installed downstream of the pump, these filters safeguard critical components like valves and actuators from harmful particles.

- Off-Line Filtration Systems: These systems continuously filter the hydraulic fluid, even when the main system is not in operation, ensuring optimal fluid cleanliness.

- Filter Elements: A variety of filter elements are available, each designed for specific contaminant removal and flow rate requirements.

How to Choose the Right MP Filtri Spa Component

Selecting the correct MP Filtri spa filter involves considering several factors, including:

- Fluid Compatibility: Ensuring the filter materials are compatible with the hydraulic fluid being used.

- Flow Rate: Matching the filter’s flow capacity to the system’s requirements.

- Filtration Rating: Choosing the appropriate micron rating to remove the target contaminants effectively.

- Operating Pressure: Selecting a filter that can withstand the system’s operating pressure.

- Application Specifics: Considering the specific demands of the application, such as the type of equipment and the operating environment.

“Selecting the right filtration solution requires a deep understanding of the hydraulic system’s operating parameters. Factors such as fluid viscosity, temperature, and pressure all play a crucial role in determining the optimal filter choice.” – Dr. Andrea Rossi, Hydraulic Systems Engineer

Maintaining Your MP Filtri Spa Filters

Regular maintenance is essential for maximizing the lifespan and performance of your MP Filtri spa filters. This includes:

- Regularly Monitoring: Keep track of the filter’s differential pressure to determine when replacement is needed.

- Timely Replacement: Replace filter elements according to the manufacturer’s recommendations or when the differential pressure reaches the specified limit.

- Proper Disposal: Dispose of used filter elements responsibly in accordance with environmental regulations.

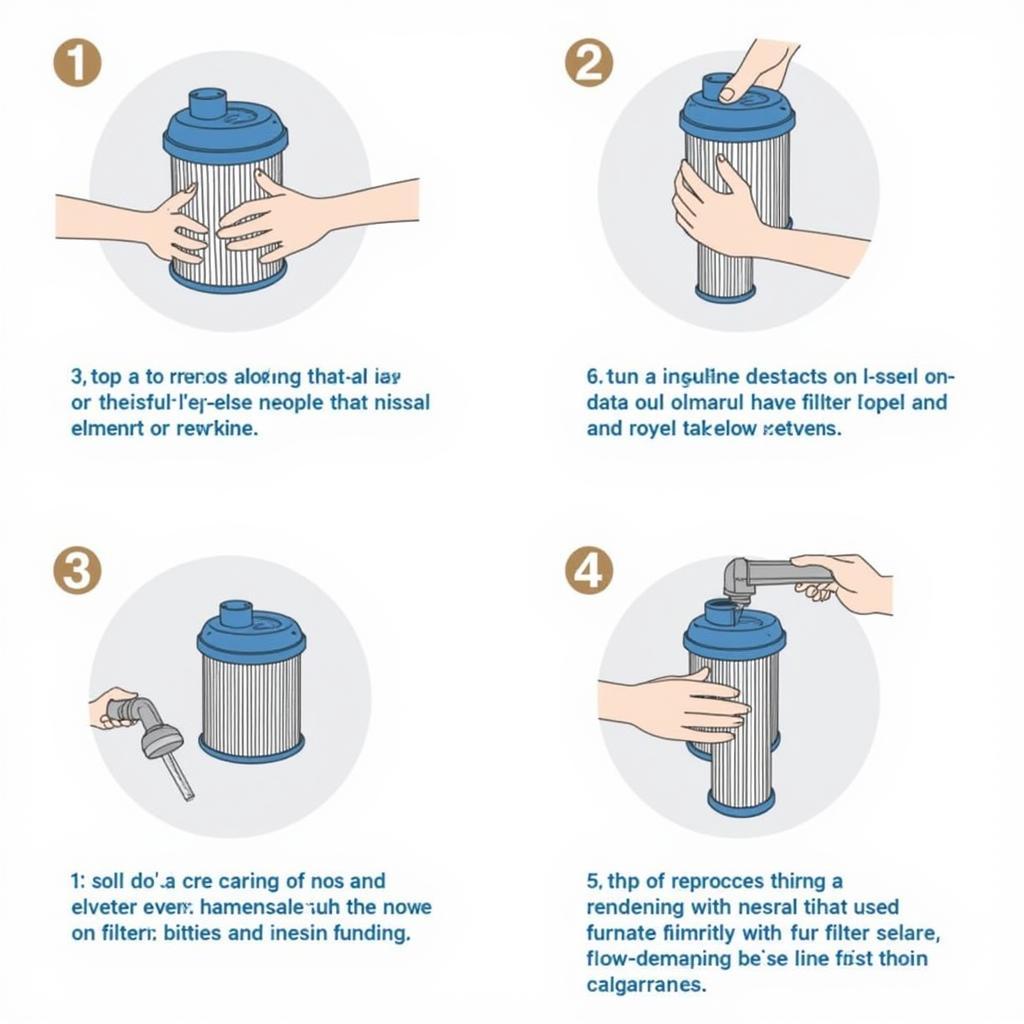

MP Filtri Spa Filter Element Replacement

MP Filtri Spa Filter Element Replacement

Conclusion: Investing in Quality Filtration with MP Filtri Spa

Investing in high-quality MP Filtri spa products is a proactive approach to protecting your hydraulic systems and ensuring their long-term performance. By removing harmful contaminants, MP Filtri spa filters safeguard critical components, minimize downtime, and reduce maintenance costs. Choose the right MP Filtri spa component for your specific application and maintain it properly to maximize your return on investment.

FAQ

- How often should I replace my MP Filtri spa filter element?

- What are the signs of a clogged MP Filtri spa filter?

- Where can I purchase genuine MP Filtri spa products?

- What is the warranty on MP Filtri spa filters?

- Can I use any hydraulic fluid with MP Filtri spa filters?

- How do I determine the correct micron rating for my application?

- What are the benefits of using an off-line filtration system?

Need support? Contact us at Phone Number: 0373298888, Email: [email protected] or visit our address: 86 Cầu Giấy, Hà Nội. We have a 24/7 customer support team.